Wrenchers Warehouse sells the Ranger RL-8500 brake lathe. It is fast, accurate and simply to use for drum and flywheel resurfacing than any other brake lathe out there in it's class. Feed rates, infinitely adjustable, easily modify cut speeds with the simple turn of a dial. For best finish results reduce or increase the cut-time whether you're speeding through your first rough cut or for a single-pass micro-finish. This complete lathe package includes: lathe; bench; and large tool storage backboards.

Vibration and chatter transfer are the most common problems that other brake lathes have and it directly affects the tool-tip and can

leave imperfect cuts on machined surfaces. The RL-8500 Brake

Lathe by Ranger eliminates the need for gear-driven mechanical drives and

variable-speed transmission devices by design.

Ranger brake lathes replaced transmission / gears found on

other brands. Brake rotors are

very smooth. If you were turning a rotor on any

lathe and drop a hammer on the floor next to the lathe you are turning, you would see a

noticeable degradation of the cut right at the moment you dropped the hammer (of impact). Vibration

causes frequencies, these frequencies get transferred to the finished cut. You won' t have this problem with the

Ranger RL-8500 brake lathe because it does not use gears and transmissions. Ranger has

completely eliminated multiple frequencies, eliminating any degradation on the

machining finish. Surface roughness is usually the

result of improper material properties, spindle rotational speed, tool feed rate, tool geometry,

and relative tool-work vibration. Vibrations and noise from gears is eliminated also.

The Ranger RL-8500 brake lathe offers more features, better performance, extra utility, best flexibility and additional productivity than you can imagine. It's the soundest investments for your business.

Trouble Free and Simple

A super-heavy, cast iron body, forged and hardened, combined with floating spindles and precision ground components makes this lather easy to operate and tough enough to withstand

the every day, all day use of a busy shop. Trust Ranger, make this one of your toughest, dependable and worry-free machines in your shop.

Service

Wrenchers Warehouse stands behind Ranger:

Ranger is a preferred supplier of quality automotive service equipment. They give their and our customers the best quality and value and provide superior service and support. Ranger is the choice of professionals worldwide. Whatever your brake service needs are, you can rely on Wrenchers Warehouse and Ranger to deliver the right equipment for the job. Why do we offer you so much more? Because we don’t just believe in selling superior products, we believe in Ranger and they believe in creating solutions that make your job easier.

| Long lasting performance

Forty years ago, Ranger introduced the design of their RL-8500 combination brake lathe. It is a favorite of brake technicians

and professionals everywhere. It's simple, fast, precise and runs

forever. Featuring a Ranger twin-cutter tool head with micrometer dials and

quick drum-to-rotor changeover. Quickly rough cut rotors or go slow and give them a fine, smooth cut using the adjustable speed settings. Variable speed allow for an

infinitely adjustable spindle-feed gear box providing finish cuts that exceed factory specs. The Ranger

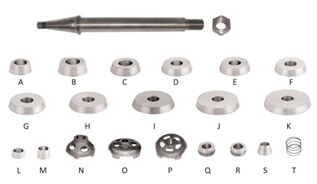

negative rake tooling yields one pass finish cuts every time. Use a multitude of tooling and adapter

choices from either Ranger or other aftermarket suppliers that fit the

standard 1" arbor.

|

|

| Look Mom No Gears! Transmission free Reduces service and repair costs because of the Ranger, by design, non existent gear-driven mechanical drives and variable-speed transmission devices.

|

|

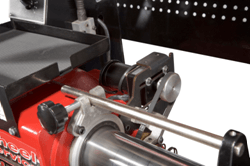

| Servo motors -dual The innovative RL8500 brake lathe uses independent DC servo motors to control the cross feed and spindle feed drives eliminating the need for complex mechanical gear boxes and transmissions |

|

|

Includes Heavy Duty Bench |

|

|

Rotors to drums change easily |

|

| Adapter package The plastic storage case holds the micro-dial twin tool cutter, 1" arbor, arbor nut, back load spring, spare bulb for lamp, illustrated instruction manual, boring bar, spacers, double-taper adapters, hub less adapters, carbide cutting tools,inside floating adapters, self-aligning spacer, outside floating adapter, centering cones, 6-sided carbide cutting inserts, wrenches, and high-impact anti-vibration bands. |

|

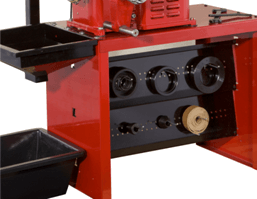

| Safe and easy to use Our ergonomic design allows you to work fast and easy. Designed for minimal operator movement there are up-front controls. Large sturdy bench with tool storage boards provide space for accessories and adapters. |

|

| Dual work lamps Keep your work area well lit with the 2 LED extra bright work lamps. |

|

| Chip catcher Large funnel and bin collects chips and keeps your shop clean and safe. |

|

| Truck adapter set - Optional Enormous multi piece set allows you to expand coverage to handle any vehicle up to 1-ton trucks. Adapter package consists of an upgraded 1 7/8" arbor and a wide variety of adapters. |

|

The Ranger RL-8500 brake lathe offers more features, better performance, extra utility, best flexibility and additional productivity than you can imagine. It's the soundest investments for your business.

- The RL-8500 uses precision electric DC servo motors, in contrast to mechanically-driven transmission, which is designed to handle demanding requirements of industrial motion control

- Eliminates the need for conventional bell clamps and cones with the Quick-Change Adapter-Plus system

- Works on foreign and domestic, cars and trucks, with hubless drums, rotors and composite rotors

- Equipped with features that increase your service capability,

- Precision twin cutter tools and a quick drum-to-rotor changeover

- spindle and cross feed speed settings, infinitely variable, makes quick rough and precision finish cuts

- Ergonomic controls for minimal operator movement

- Easy to learn and master.

- Maintains accuracy

- Heavy duty components, such as a precision ground spindle (that resists grooving) and makes boots obsolete

- Massive tapered spindle bearings for weight support

- "Splash-lube" oil-feed system for a constant flow of oil to the bearings

- Faster, quieter operation, reduced noise and vibration because we use a Serpentine belt

- Independent cross-feed motor eliminates shear gears

- Top storage tray - tools are kept within short reach

- Separate drum and rotor motors maximize efficiency

- Standard adapter package includes Quick-Change hub less adapter system

- Machine all standard and composite rotors for foreign and domestic cars and light trucks using the variety of adapters included

- Cast iron body and a solid work bench weighing 450-lb. reduces transient vibrations

- Choose 150 or 200 rpm to easily change arbor speeds in seconds: depending on the job

- 1-pass finish virtually every time using positive rake cutter tip angle allowing you to complete your work faster and better

- Truck adapter kit available - Optional

- Motor drive unit: 115 – 230 VAC / 50 – 60 Hz / 1 Ph / 20 amp

- Max rotor thickness: 2 1/2"

- Max rotor diameter: 17"

- Spindle travel: 6 7/8"

- Spindle speed: 150 rpm – 200 rpm

- Weight (shipping) including bench and tools: 685 lbs.

- Shipping dimensions: 62" x 49" x 36"

- Brake drum diameter: 6" – 28"

- Max load with standard 1" arbor: 150 lbs.

- Max load with optional 1-7/8" truck arbor: 250 lbs.

Featured accessories for the RL-8500

Quick Specs

| Max drum diameter: | 28" |

| Max rotor thickness: | 2 1/2" |

| Max rotor diameter: | 17" |

| Max load / 1" arbor: | 150 lbs. |

| Max load / 1 7/8" arbor: | 250 lbs. |

| Max spindle speed: | 200 rpm |

| Spindle travel: |

6 7/8" |

| Voltage: | 115-230VAC |